As technology advances, the possibilities for printing on different materials are expanding. No longer limited to just paper, printers can now handle a variety of surfaces and materials, allowing for unique and creative results. With advancements in digital textile printing technology, fabrics have become a popular choice for printing. This allows for high-quality prints on various fabrics such as cotton, silk, polyester, and more. Heat press machine reviews amazon, for instance, even highlight the machines’ popularity and wide use in the textile industry. In addition to fabrics, metals have also become a popular choice for printing. With advancements in metal 3D printing, intricate designs can now be created with ease.

Embracing Fabric Printing

Digital textile printing has revolutionized the fashion and interior design industries. It allows for more flexibility in designs and shorter production times compared to traditional methods such as screen printing. Digital textile printers use inkjet technology to print directly onto the fabric, producing high-quality prints with vibrant colors and intricate details. This method also allows for more sustainable practices, eliminating the need for excessive amounts of water and chemicals used in traditional textile printing methods.

Cotton and Polyester Fabrics

Cotton and polyester fabrics are the staple canvas for printing. They absorb ink well, offering vibrant and durable prints. Techniques like heat transfer, screen printing, or sublimation bring designs to life on garments, bags, or home textiles. These fabrics can handle repeated washing and wear, making them ideal for everyday use.

Silk and Satin Fabrics

Silk and satin fabrics offer a luxurious canvas for printing. Their smooth, shiny surfaces allow for crisp and vibrant prints. Digital textile printing has made printing on these delicate fabrics possible without damaging the fibers or losing their luster. This opens up new possibilities for high-end fashion and home decor items.

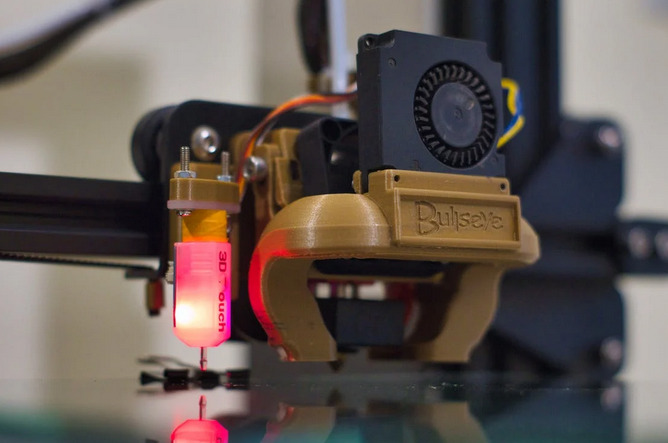

Metal Printing

While fabric printing has seen significant advancements, metal printing has also made strides in recent years. Metal 3D printers use various techniques, such as powder bed fusion or directed energy deposition, to create complex designs with precision. This technology is not only used for artistic purposes but also in industries like aerospace and automotive, where lightweight but strong metal components are needed.

Expanding Possibilities on Other Materials

The advancements in printing technology have also paved the way for printing on other materials such as wood, glass, and even food items. This allows for endless possibilities in creating custom and personalized products. For example, you can now print intricate designs onto wooden furniture or add a personal touch to glassware with ease.

The art of printing spans beyond traditional fabrics, unveiling a tapestry of materials awaiting creative exploration. By embracing diverse printing techniques and materials, artisans can transform ordinary surfaces into personalized masterpieces. Venture into the vast world of printing, experimenting with different materials and techniques. Whether it’s garments, metals, ceramics, or woods, each surface becomes a canvas for your imagination, a testament to the boundless possibilities of the printing craft.